Welding has come a long way since the days of the rudimentary processes of the early 20th century. With the advent of inverter welding, the industry has taken a giant leap forward in the direction of precision, efficiency, and safety. The journey of inverter welding from its humble beginnings to its current state of dazzling technology has been an exciting one. Let’s shine a light on its history and explore the sparkling tales of inverter welding.

Shining a Light on the History of Inverter Welding!

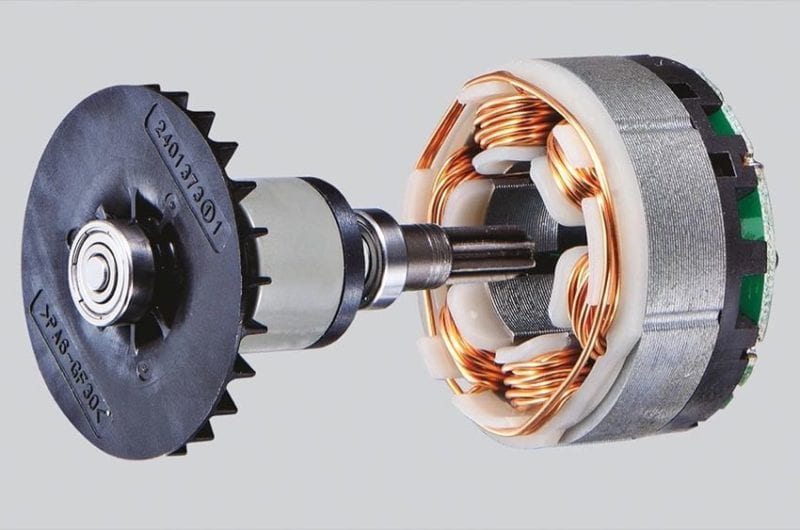

The invention of inverter welding can be traced back to the 1960s, when a German scientist, Dr. Fritz Wagner, developed the first inverter welder. This new technology was a departure from the conventional transformer-based welders. It used a high-frequency inverter to convert the low voltage, high amperage power supply into a high voltage, low amperage supply, which made it possible to achieve precise control over the welding arc. This technology was first used in the aerospace industry, where the need for precision welding was paramount.

In the 1980s, inverter welding technology began to find its way into other industries. Its advantages over transformer-based welders were quickly recognized, including its portability, lower power consumption, and greater control over the welding arc. With time, inverter welding became the preferred method of welding for many industries, including construction, shipbuilding, and automotive manufacturing. Today, inverter welding is a widely used and respected technology, with its applications expanding into new fields of engineering.

From Humble Beginnings to a Dazzling Future: Sparkling Tales of Inverter Welding!

The future of inverter welding is a bright one. This technology is constantly evolving, with new advancements being made in areas such as efficiency, automation, and safety. Today, inverter welding machines are equipped with features such as digital controls, pulsing, and wave-shaping, which allow for even greater precision and control over the welding process. Automated inverter welding systems have also been developed, which enable welders to work on complex projects with greater ease and efficiency.

In conclusion, the history of inverter welding is a sparkling tale of innovation and progress. From its humble beginnings in the aerospace industry to its current state of technological excellence, inverter welding has come a long way. With its precision, efficiency, and safety, it is now the preferred welding method for many industries. The future of inverter welding is even brighter, with new advancements on the horizon that promise to make this technology even more efficient and versatile.