Top 10 Advantages of Brushless Motors in Cordless Power Tools, As cordless tools continue to revolutionize the world of professional and DIY projects, brushless motors have become a crucial innovation, offering enhanced performance and durability. In this comprehensive guide, we will explore the benefits of brushless motors, discuss different types, and highlight the advantages they bring to cordless drills compared to brushed alternatives.

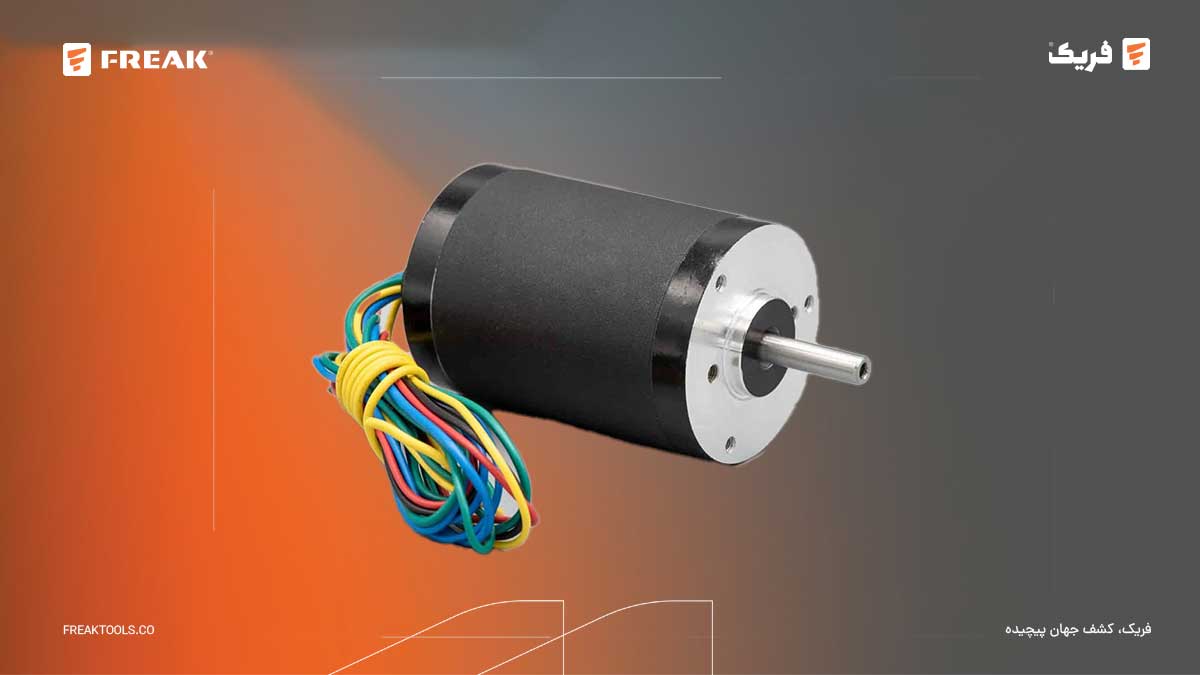

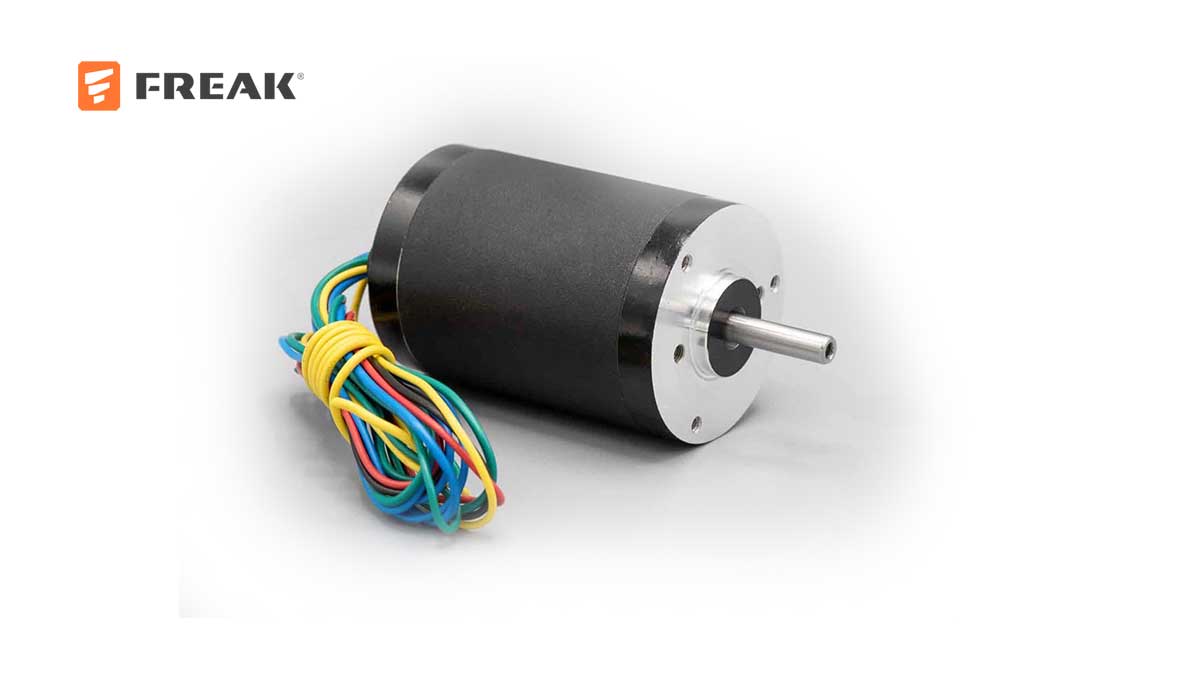

What is a Brushless Motor?

A brushless motor is a type of electric motor that operates without the carbon brushes commonly found in traditional motors. Unlike brushed motors, where mechanical brushes create physical contact with a spinning commutator, brushless motors use electronic control to generate magnetic fields that move the motor shaft. This eliminates the need for brushes, which significantly reduces friction and wear.

How Does a Brushless Motor Work?

In brushless motors, a small electronic circuit manages the distribution of electrical current, allowing the rotor to spin smoothly without the need for direct contact. This efficient operation reduces energy loss and enhances the overall performance of the motor. By eliminating physical contact between components, brushless motors achieve greater efficiency, higher torque, and increased lifespan, especially in demanding applications.

Types of Brushless Motors in Power Tools

1. Inrunner Brushless Motors

Inrunner brushless motors have their magnets located inside the motor’s casing, allowing them to generate high rotational speeds and torque. These motors are widely used in cordless drills, impact drivers, and other tools that require high rotational force. Their design makes them efficient in applications where space is limited, without compromising performance.

2. Outrunner Brushless Motors

Outrunner brushless motors have the magnets on the outer rotor, which increases torque output. While these motors tend to rotate at lower speeds compared to inrunner models, they are favored in applications requiring high torque at lower speeds. They are ideal for specialized equipment like electric bikes but can also be found in certain high-torque power tools.

Applications of Brushless Motors in Cordless Tools

The efficiency and reliability of brushless motors make them ideal for various cordless tools. Brushless motors can be found in power drills, impact drivers, saws, grinders, and even lawn equipment. Their versatile applications have set a new standard for power tools by delivering consistent performance, longer runtime, and reduced maintenance.

Top 10 Advantages of Brushless Motors in Cordless Power Drills

1. Enhanced Energy Efficiency

Brushless motors consume less energy due to the absence of mechanical friction, which translates into longer battery life. This efficiency is especially beneficial for cordless drills, where consistent power output and prolonged usage are essential.

2. Increased Power and Performance

A key advantage of brushless motors is their ability to generate higher torque and power output compared to brushed motors of the same size. This enhanced power allows cordless drills equipped with brushless motors to tackle tougher materials, making them ideal for heavy-duty tasks.

3. Reduced Heat Production

Brushless motors produce less heat because there is no friction caused by brushes. Lower heat production prevents overheating, ensuring that the drill performs consistently even under continuous or intense usage. For users, this means greater comfort and prolonged operation without needing frequent breaks.

4. Longer Lifespan and Durability

The elimination of brushes in these motors significantly reduces wear and tear, contributing to a longer lifespan. A brushless motor can last up to three times longer than a brushed motor, making it a cost-effective choice for professionals and hobbyists who need reliable tools.

5. Less Maintenance

With no brushes to replace or parts to clean frequently, brushless motors offer a maintenance-free experience. This reduces the overall cost of ownership and eliminates the hassle of regular servicing, making cordless drills with brushless motors a low-maintenance, high-reliability option.

6. Compact and Lightweight Design

Brushless motors are generally more compact and lightweight than brushed motors, allowing manufacturers to design smaller, ergonomically-friendly tools. This design is advantageous for cordless drills, as it enables easier handling, especially during prolonged use or when working in confined spaces.

7. Variable Speed Control for Precision

Brushless motors offer improved control over speed and torque, providing a smoother and more precise drilling experience. The absence of mechanical brushes enables real-time adjustments, giving users better control over the tool’s speed, which is particularly useful when working with different materials.

8. Quiet Operation

Cordless tools with brushless motors operate more quietly due to the absence of brush friction, which can be beneficial in residential or indoor work environments. This reduced noise makes brushless cordless drills ideal for jobs that require lower noise levels without sacrificing power.

9. Intelligent Technology Integration

Brushless motors in modern cordless drills are often integrated with smart sensors and microprocessors. These technologies adjust power output, detect resistance, and optimize performance for different applications. This intelligent system helps in conserving battery power, ensuring maximum efficiency, and preventing motor damage.

10. Consistent and Reliable Performance

Finally, brushless motors deliver consistent performance even under demanding conditions. With the ability to maintain power and efficiency in high-demand applications, cordless drills with brushless motors ensure reliable performance throughout their lifespan. This consistency is crucial for professionals who depend on their tools for accuracy and productivity.

Comparing Brushless and Brushed Motors in Cordless Drills

When comparing brushless and brushed motors in cordless drills, the differences are striking. Brushed motors rely on physical contact between brushes and a commutator, resulting in higher friction, energy loss, and increased heat. These factors impact efficiency, longevity, and power output, especially in intense applications.

Conversely, brushless motors eliminate the need for physical contact, reducing heat and friction while maximizing efficiency. In practical terms, cordless drills with brushless motors are typically more powerful, longer-lasting, and less prone to breakdowns. While brushed motors may be suitable for basic tasks, they are limited in performance compared to brushless technology, especially in demanding environments.

Why Brushless Motors are Essential for Cordless Drills

The importance of brushless motors in cordless drills cannot be overstated. For anyone involved in regular or professional drilling tasks, the added benefits of durability, reliability, and control make brushless technology a worthy investment. The advantages of a brushless motor in a cordless drill include:

- Extended Battery Life: Improved energy efficiency allows for more work per charge.

- Greater Torque and Power: Enhanced power makes it easier to drill into hard materials like concrete or metal.

- Reduced Maintenance Costs: Fewer moving parts mean less maintenance and reduced cost over time.

- Compact Design: The smaller size of brushless motors allows for more ergonomic and portable drills.

- Intelligent Performance Adjustments: Integrated sensors can optimize performance automatically.

These features contribute to a significantly better user experience and make brushless drills highly recommended for both DIY enthusiasts and professionals. Although drills with brushless motors might have a higher upfront cost, the return on investment in terms of longevity and reliability is well worth it.